Our 3 D Phase Process

Product success is the byproduct of good design, and extraordinary design is the result of an exceptional process that prioritizes partnerships with forward thinking clients that are open to innovation

Discover

Every Cruver Design project starts wherever you’re at in your own process. Our discovery process adapts perfectly to your unique needs, setting the stage for success every time.

Design

Our entire design workflow is built to ensure a user-first, feature-forward product through a process that fuses the creative with the technical, while keeping every stakeholder effortlessly involved.

Deliver

Our goal is more than just delivering raw design. We provide all the tools and support needed to deliver engineer-ready products primed and ready for execution.

Why Our Process

Every step of our iterative process is designed to transform your ideas into innovative, user-focused products that excel in the marketplace. Whether you’re starting from scratch, improving an existing design, or somewhere in between, we adapt to you, your needs, and your goals.

Our process also puts the focus squarely on the end-user. By prioritizing usability, ergonomics, and strategic thinking, we help you explore the boundaries of what’s possible in product design. The result: innovative, feature-forward, human-centered designs that delight users, challenge the status quo, and break through markets.

Phase One: Discover

Phase One: Discover

Requirements Analysis

Understanding your vision is where success begins. We dive deep into your goals, market, and user needs to set clear project

parameters from the start. This step starts during the proposal stage so we can hit the ground running at project launch.

Deliverables include careful analysis of product usability, competitive analysis, market needs, Concept Renderings and manufacturing

considerations.

Phase One: Discover

Research & Data Gathering

When more insights are needed, we’ll conduct user, market, and competitor research. This critical step ensures the design is grounded

in actual user needs and preferences, laying a rock-solid foundation for a competitive, successful product.

Deliverables might include Product Analysis and Market Research, which our clients can review with us to ask any questions or provide

insights and feedback of their own.

Phase One: Discover

Initial Concepting

Next, we want to generate a range of new concepts from which you can choose. This phase can occur at the same time as others, like Ergonomic

Analysis, or on its own. We might even start here, depending on your needs. Regardless, we use this opportunity to explore many possible

variations within the given parameters, in some cases as hand drawn sketches or illustrated with 3D Concept Renderings created from Rendering

Geometry, so you can visualize your product’s aesthetics and functionality early on, before extensive time and resources are expended.

Deliverables typically include detailed Ideation Studies in the form of Hand Sketches, CAD Sketches, or full color Concept Renderings. From

here, the next step can move in any of several different directions: further research, continued concepting, or Ergonomic Analysis using physical

Mock-ups created from a variety of materials including 3D prints.

Phase One: Discover

Ergonomic Analysis

Products are made for end users (a foundational principle often overlooked by many industrial designers). Our ergonomic analysis focuses on usability and comfort, with studies and real-world feedback to optimize the user experience. The result? Products users genuinely love. The timing of this step varies, as it sometimes comes during discovery; other times, we need to wait until we have a full CAD model and/or 3D print.

Phase One: Discover

Requirements Analysis

Understanding your vision is where success begins. We dive deep into your goals, market, and user needs to set clear project parameters from the start. This step starts during the proposal stage so we can hit the ground running at project launch.

Deliverables include careful analysis of product usability, competitive analysis, market needs, Concept Renderings and manufacturing considerations.

Phase One: Discover

Research & Data Gathering

When more insights are needed, we’ll conduct user, market, and competitor research. This critical step ensures the design is grounded in actual user needs and preferences, laying a rock-solid foundation for a competitive, successful product.

Deliverables might include Product Analysis and Market Research, which our clients can review with us to ask any questions or provide insights and feedback of their own.

Phase One: Discover

Initial Concepting

Next, we want to generate a range of new concepts from which you can choose. This phase can occur at the same time as others, like Ergonomic Analysis, or on its own. We might even start here, depending on your needs. Regardless, we use this opportunity to explore many possible variations within the given parameters, in some cases as hand drawn sketches or illustrated with 3D Concept Renderings created from Rendering Geometry, so you can visualize your product’s aesthetics and functionality early on, before extensive time and resources are expended.

Deliverables typically include detailed Ideation Studies in the form of Hand Sketches, CAD Sketches, or full color Concept Renderings. From here, the next step can move in any of several different directions: further research, continued concepting, or Ergonomic Analysis using physical Mock-ups created from a variety of materials including 3D prints.

Phase One: Discover

Ergonomic Analysis

Products are made for end users (a foundational principle often overlooked by many industrial designers). Our ergonomic analysis focuses on usability and comfort, with studies and real-world feedback to optimize the user experience. The result? Products users genuinely love. The timing of this step varies, as it sometimes comes during discovery; other times, we need to wait until we have a full CAD model and/or 3D print.

Phase Two: Design

Phase Two: Design

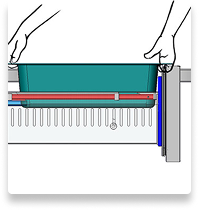

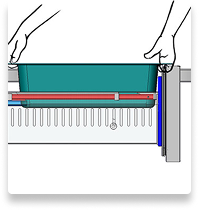

Ergonomic Design

Products are made for end users, which means form and function must meet in perfect marriage. Through a relentless focus on optimizing usability and comfort, we can design products users genuinely love to use.

Deliverables include Ergonomic Diagrams, and documented testing and analysis of physical Mock-ups.

Phase Two: Design

Refined Industrial Design

With your feedback in hand, we refine the initial concepts, ensuring it meets the needs of the user, the marketing strategy, and manufacturing. The updated design is rendered to a high level of detail to provide a photorealistic preview of the finished product. As a sub-step, this phase may include developing Product Branding or a user-friendly Graphic User Interface (GUI) that facilitates successful use of the product.

Deliverables may include: Concept Renderings, Graphic Artwork for Branding, Graphic Artwork for control panels, GUI Mock-ups for LCD touchscreen interfaces.

Phase Two: Design

Ergonomic Design

Products are made for end users, which means form and function must meet in perfect marriage. Through a relentless focus on optimizing usability and comfort, we can design products users genuinely love to use.

Deliverables include Ergonomic Diagrams, and documented testing and analysis of physical Mock-ups.

Phase Two: Design

Refined Industrial Design

With your feedback in hand, we refine the initial concepts, ensuring it meets the needs of the user, the marketing strategy, and manufacturing. The updated design is rendered to a high level of detail to provide a photorealistic preview of the finished product. As a sub-step, this phase may include developing Product Branding or a user-friendly Graphic User Interface (GUI) that facilitates successful use of the product.

Deliverables may include: Concept Renderings, Graphic Artwork for Branding, Graphic Artwork for control panels, GUI Mock-ups for LCD touchscreen interfaces.

Phase Three: Deliver

Phase Three: Delivery

Ergonomic Validation

We can only ensure ergonomic success once we have checked and verified that the ergonomics of the product work as intended. Our process thus necessarily involves a series of checks and quality assurance to ensure the product successfully delivers the user experience for which it was designed.

Phase Three: Delivery

Prototype Design:

CAD Geometry

Next, we build Prototype Geometry: a precise 3D prototype model that accommodates interior components, clearances, surface draft and assembly features, with quality checks performed based on your specifications. It’s your product—fully defined and ready for next steps.

Deliverables include the Prototype Geometry and Artwork for graphics as needed.

Phase Three: Delivery

Prototype Bill of Materials

We will then generate a full Bill of Materials (B.O.M.) from the SolidWorks Prototype Geometry. This captures every detail, clearly documented. Our Prototype B.O.M. outlines materials, colors, finishes, and part names and descriptions—all paired with visuals to show how the parts are assembled, ensuring seamless handoffs to engineering and manufacturing teams.

The B.O.M. is shared with management, engineering, and manufacturing to ensure all relevant parties have a full understanding of the design intent.

Phase Three: Delivery

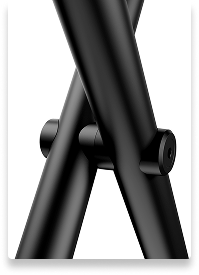

Prototype Build

A prototype model is built to accurately represent the new product design; considering aesthetics, parts, service, industry standards, materials, and manufacturing processes. Precise prototypes are made using rapid prototyping processes such as: CNC machining and 3D printing. For multiple prototypes, we offer silicone rubber molds for casting multiple parts in Urethane with threaded brass inserts. When needed, metal components like painted steel, machined aluminum, and stainless steel parts can be provided.

Deliverables include a functional prototype

and evaluation.

Phase Three: Delivery

Ergonomic Validation

We can only ensure ergonomic success once we have checked and verified that the ergonomics of the product work as intended. Our process thus necessarily involves a series of checks and quality assurance to ensure the product successfully delivers the user experience for which it was designed.

Phase Three: Delivery

Prototype Design:

CAD Geometry

Next, we build Prototype Geometry: a precise 3D prototype model that accommodates interior components, clearances, surface draft and assembly features, with quality checks performed based on your specifications. It’s your product—fully defined and ready for next steps.

Deliverables include the Prototype Geometry and Artwork for graphics as needed.

Phase Three: Delivery

Prototype Bill of Materials

We will then generate a full Bill of Materials (B.O.M.) from the SolidWorks Prototype Geometry. This captures every detail, clearly documented. Our Prototype B.O.M. outlines materials, colors, finishes, and part names and descriptions—all paired with visuals to show how the parts are assembled, ensuring seamless handoffs to engineering and manufacturing teams.

The B.O.M. is shared with management, engineering, and manufacturing to ensure all relevant parties have a full understanding of the design intent.

Phase Three: Delivery

Prototype Build

A prototype model is built to accurately represent the new product design; considering aesthetics, parts, service, industry standards, materials, and manufacturing processes. Precise prototypes are made using rapid prototyping processes such as: CNC machining and 3D printing. For multiple prototypes, we offer silicone rubber molds for casting multiple parts in Urethane with threaded brass inserts. When needed, metal components like painted steel, machined aluminum, and stainless steel parts can be provided.

Deliverables include a functional prototype

and evaluation.

Our Awards

Follow-Up

We deliver more than just designs—we deliver results. Our goal is to provide an engineer-ready product that accelerates your path to production. That means you will have everything you need from a design perspective to complete the engineering phase of the project as efficiently as possible.

But we don’t stop there. Need referrals for engineers or manufacturers, or help with user testing? We are dedicated to providing the support needed for you to meet your objectives; your success is our success. At every stage, we’re your partners—focused from start to product launch to help you create a standout product that represents the ideal version of your initial vision and ultimately drive market success.